Influence of Framework Material and Posterior Implant Angulation in Full-Arch All-on-4 Implant-Supported Prosthesis Stress Concentration

1 Department of Dental Materials, Academic Centre for Dentistry Amsterdam (ACTA), University of Amsterdam and Vrije Universiteit Amsterdam, 1081 LA Amsterdam, The Netherlands

2 Department of Dental Materials and Prosthodontics, Institute of Science and Technology, São Paulo State University-UNESP, São José dos Campos 12220-000, Brazil

3 Fraunhofer JL IDEAS, Department of Industrial Engineering, University of Naples Federico II, 80125 Naples, Italy

4 School of Dentistry, University of Naples Federico II, Via S. Pansini 5, 80131 Naples, Italy

* Author to whom correspondence should be addressed.

Dent. J. 2022, 10(1), 12; https://doi.org/10.3390/dj10010012

Abstract

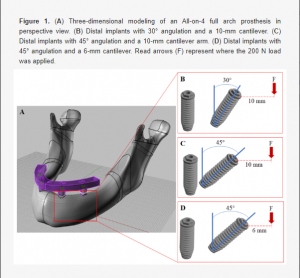

This study evaluated the influence of distal implants angulation and framework material in the stress concentration of an All-on-4 full-arch prosthesis. A full-arch implant-supported prosthesis 3D model was created with different distal implant angulations and cantilever arms (30° with 10-mm cantilever; 45° with 10-mm cantilever and 45° with 6-mm cantilever) and framework materials (Cobalt–chrome [CoCr alloy], Yttria-stabilized tetragonal zirconia polycrystal [Y-TZP] and polyetheretherketone [PEEK]). Each solid was imported to computer-aided engineering software, and tetrahedral elements formed the mesh. Material properties were assigned to each solid with isotropic and homogeneous behavior. The contacts were considered bonded. A vertical load of 200 N was applied in the distal region of the cantilever arm, and stress was evaluated in Von Misses (σVM) for prosthesis components and the Maximum (σMAX) and Minimum (σMIN) Principal Stresses for the bone. Distal implants angled in 45° with a 10-mm cantilever arm showed the highest stress concentration for all structures with higher stress magnitudes when the PEEK framework was considered. However, distal implants angled in 45° with a 6-mm cantilever arm showed promising mechanical responses with the lowest stress peaks. For the All-on-4 concept, a 45° distal implants angulation is only beneficial if it is possible to reduce the cantilever’s length; otherwise, the use of 30° should be considered. Comparing with PEEK, the YTZP and CoCr concentrated stress in the framework structure, reducing the stress in the prosthetic screw.

Keywords:

dental implants; finite element analysis; polymers; prosthodontics

1. Introduction

Implant prostheses rehabilitation has proven efficacy in the treatment of fully edentulous patients in long-term studies [1,2]. However, the process of bone resorption due to physiological and pathological factors [3] complicates planning for the installation of posterior implants as a prosthetic support [4,5].

The All-on-4 concept [6] consists of the installation of four implants in the medial region of the maxilla or jaw to support fixed or removable prostheses that are immediate, provisional or definitive. Two mesial implants are usually placed perpendicular to the bone crest, and two distal implants are installed inclined, reducing the distal cantilever and allowing replacement of more teeth [7,8,9,10,11]. The predictability and safety of this type of treatment has been already described in the literature [6,12,13,14,15]. During the distal implant installation, different angulation can be used according to surgical planning. However, the literature is not concise regarding the benefits of 30° and 45° angulation for reducing stress concentration [16,17]. It is important to note that the surgeon inserted inclined distal implants to reduce the cantilever length, and this variable should be considered when analyzing prosthetic modality.

In an implant-supported full-arch total prosthesis, it is necessary to use a framework on which artificial teeth are fixed [18]. Among the materials available for the framework, alloys stand out due to their sufficient tensile strength (>300 MPa) and elastic modulus (>80 GPa), which prevent plastic deformations of cantilevers [19]. For that, the CoCr (Cobalt–chrome) alloy is widely used.

With the advent of CAD/CAM technology and increased demand for metal-free prostheses, yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) has been used as an alternative to metal in dental treatments [20]. The use of zirconia allows framework masking and presents a similar survival rate to metal [21,22,23]. Another possibility is the use of polyetheretherketone (PEEK), a high-performance polymer initially applied in orthopedics as a substitute for titanium [24] and currently used in dentistry for the manufacture of implants, frameworks, removable partial dentures and crowns [25,26,27,28,29].

While a metal framework presents an elastic modulus that ranges between 100 and 200 GPa, PEEK presents approximately 4 GPa [26]. Regardless of this difference between the mechanical properties of these materials, it is assumed that PEEK is an alternative material for the manufacture of fixed prosthesis frameworks on implants [28,29]. However, its behavior against the application of stresses should be evaluated.

In this sense, theoretical analysis, e.g., finite element analysis, could be advantageous for investigating the origins of mechanical failure mechanisms around dental implants. This numerical tool can assess stresses and help formulate hypotheses regarding dental implants behavior [30,31,32].

Therefore, the purpose of this study was to evaluate the mechanical behavior in the All-on-4 concept prosthesis with different framework materials (CoCr, YTZP and PEEK) and different distal implants positioning. The null hypothesis was that the use of different framework material and posterior implant position would not affect the prosthesis’ mechanical behavior.

2. Materials and Methods

A virtual model of a jaw without maxillofacial abnormalities was exported in DICOM format from the São Paulo State University database. The DICOM file was converted to STL (stereolithography) file in a 3D slicer software. Using the CAD software (Rhinoceros Version 4.0 SR8, McNeel North America, Seattle, WA, USA), a model of an edentulous jaw was created following the main anatomical characteristics of an adult bone: size, shape and absence of pathology [27]. The BioCad method was applied to create a volumetric and solid model [33]. For that, the anatomical surface of the jaw has been delimited by polylines, and the intersection of three or four polylines has been used to form a network surface. The association of juxtaposed and joined surfaces formed the final volume of the 3D model. In sequence, external hexagon implants (10 × 4.1 mm) were created with the external thread diameter being established according to the dimensions provided by the manufacturer (Conexão Sistemas de Prótese, Arujá, Brazil) [18]. The platform had a diameter of 4.1 mm, and the external hexagon presented 0.7 mm of height. The minimum distance between the implants was 4 mm [18,20].

Three different models were created according to distal implant positioning in relation with the implant’s long-axis: 30° with a 10-mm cantilever (30°/10 mm), 45° with a 10-mm cantilever (45°/10 mm) or 45° with a 6-mm cantilever (45°/6 mm).

In this study, the 30° angled implant was considered as a starting point for the All-on-4 technique. Normally, the an All-on-4 concept is performed with two posterior inclined implants. However, implant inclination should be carefully considered during the treatment plan, because it is possible to incline the implant apex or the implant platform to achieve 45° of inclination. The first situation (apex) will keep the cantilever arm similar to the starting point (30°), increasing only the angle of insertion, while the second situation (platform) can reduce the cantilever arm at 40%. For all simulated models, the framework bar that received the load presented the same extension (In Figure 1, the load region in F is similar regardless the model). For that reason, we did not consider 30° with the cantilever of 6 mm, as it would represent a reduction in the extension of the bar and, therefore, a different quantity in the number of teeth.

Figure 1. (A) Three-dimensional modeling of an All-on-4 full arch prosthesis in perspective view. (B) Distal implants with 30° angulation and a 10-mm cantilever. (C) Distal implants with 45° angulation and a 10-mm cantilever arm. (D) Distal implants with 45° angulation and a 6-mm cantilever. Read arrows (F) represent where the 200 N load was applied.

The framework presented a height of 6 mm from the bone surface and the lever arm following the implant platform position. The screw access holes were created to simulate a clinical situation. Finally, at the end of the framework, a 2-mm diameter delimitation was created to standardize load application [29,33]. The 3D prosthetic screw was modeled for each implant. The geometry designs are presented in Figure 1.

Each solid geometry was imported to the finite element software (ANSYS 17.2, ANSYS Inc., Houston, TX, USA) in STEP format. A 3D mesh was generated, and tetrahedral elements were used. A convergence test of 10% determined the total number of elements and nodes for each model (Table 1).

To download The full article in PDF format please click on this link: DOWNLOAD ARTICLE PDF

For Surgical Guide Inquiries, Please Click on this link: SURGICAL GUIDE INQUIRY